ISO 9001 is the International Standard for Quality Management Systems, first published in 1987 by the International Organisation for Standardisation (ISO), it is one of the most commonly used management tools across the world.ISO 9001 is designed to help organisations ensure that they meet the needs of customers and other stakeholders, by having a framework in place that helps ensure consistent quality in the provision of goods and/or services.

An ISO 9001 Quality Management System (QMS) will help you

streamline your processes, reduce errors, free up valuable management time and improve internal communications.

Companies adopting this approach benefit from increased employee morale, improved customer retention and healthier

revenues.In short, through certification to ISO 9001 you demonstrate that your organisation is customer-focused and

committed to delivering high quality services.Here are the top benefits of using the ISO 9001

framework:Increased efficiency: by following industry best-practice and focusing on quality you

can reduce costs.Increased revenue: through the reputation of ISO 9001 you can win more

tenders and contracts, and by being more efficient you will also retain more customers and experience more repeat

custom.Higher levels of customer satisfaction: by understanding your customers’ needs and

reducing errors you increase customer confidence in your ability to deliver products and

services.

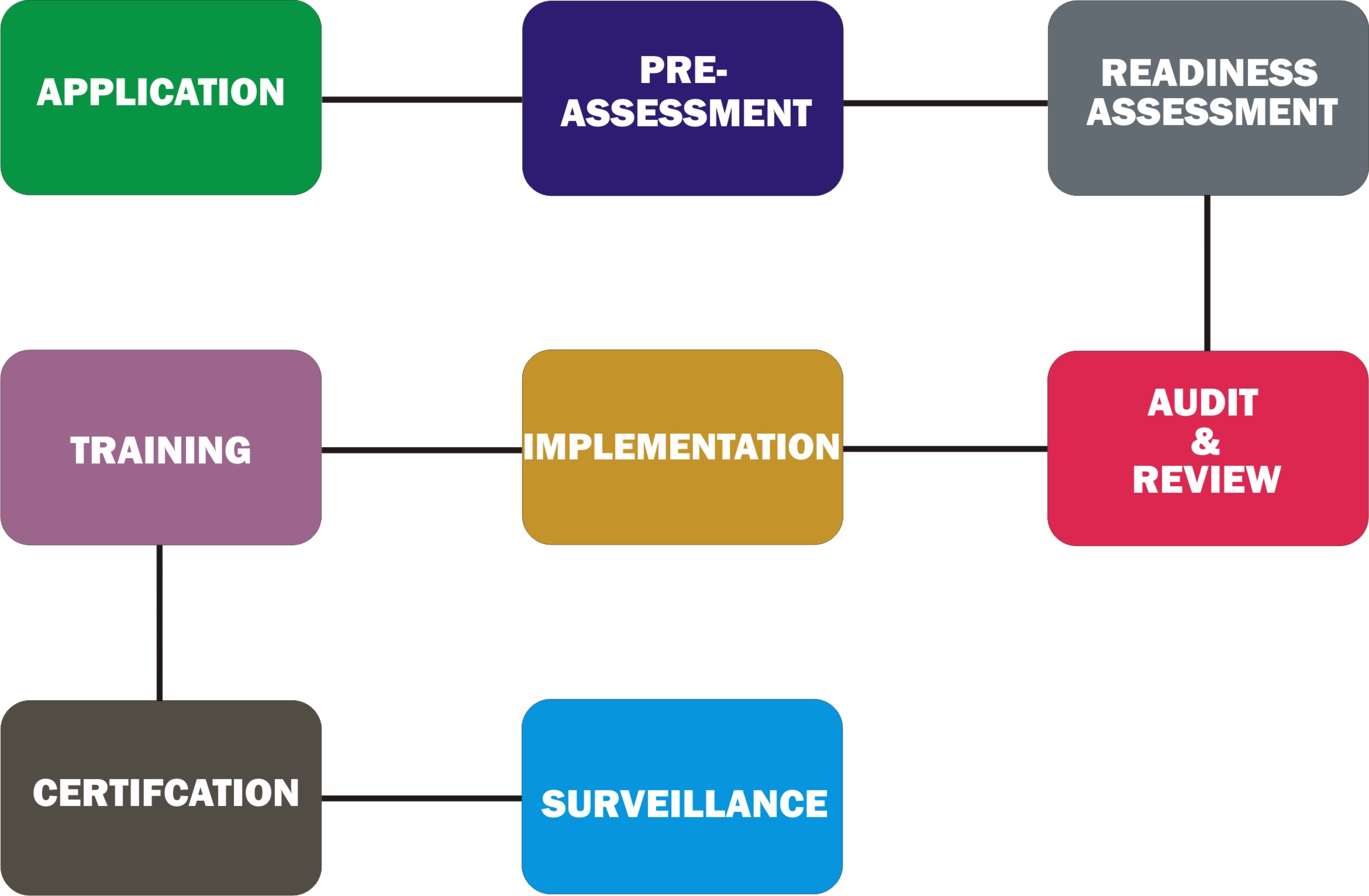

These are some of the items that may be required for the ISO certification process, assessors may require more but your company need to have this basic information ready

Note* - that in case you do now have any of the listed information, our assesors and consultants will work with you to put them in place. You may still go ahead with your application.